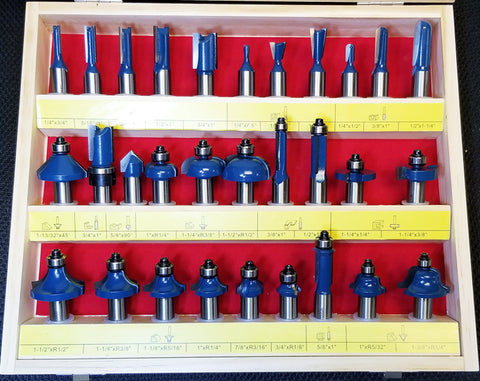

Modern Materials Finishing Geometry (MMFG) incorporates high shear, multi-flute and a ZrN coating designed for the ultimate combination of finish and tool longevity in engineered materials. Today's materials present challenges to the fabricator using these special multi-flute edge tools featuring ZrN ceramic coating addresses these challenges with a winning geometry combination.

Excellent for cutting:

- Plastic

- Acrylic Stone

- Aluminum

- Acrylonitrile-Butadiene-Styrene (ABS)

- Carbon Fiber Reinforced Polymer (CFRP)

- Composite

- Corian

- Coroplast®*

- Fiberglass

- Fiberglass PCB Board

- HDPE

- High Impact Polystyrene (HIPS)

- Low Density Polyethylene (LDPE)

- Phenolics

- Poly (methyl methacrylate) (PMMA)

- Polycarbonate (Lexan™)†

- Polyethylene Terephthalate Glycol-Modified (PETG / PET-G)

- Thermoplastic Polyolefin (TPO)

*A soft plastic cardboard made with super soft super flexible PVC.

†Recommendation: Use the slowest suggested feed rates and the shortest bits necessary for cutting and routing Lexan™.

About our ZrN Coating

- Creates a harder and tougher cutting edge allows for a prolonged cutting edge life and helps to prevent the build-up of material in the flutes while cutting

- High resistance to wear

- Extended tool life

- Less friction & heat buildup

- High resistance to wear

SPIRAL COMPOSITE, FIBERGLASS AND PHENOLIC CUTTING

QUESTIONS & ANSWERS

Have a Question?

Be the first to ask a question about this.