Produced by following state-of-the-art processes and by using high-tech machines, these jig saw blades have been specifically designed for precise cuts on soft & hardwood, plywood, OSB, laminates, plastics, HPL, multiplex panels, metals, ferrous & non-ferrous materials, aluminium, fiberglass and also stainless steel. These are made of three different materials:

HCS (high carbon steel). For use when cutting softwood, wood fiberboard and soft plastic.

BIM (bimetal). Suitable for use in hardwood, abrasive wooden and harder materials such as non-ferrous and ferrous metals. This special bond of HCS and HSS fits the most diverse needs. Resistant to shank breakage thanks to its flexibility, this material lasts much longer than HCS and HSS. An excellent value for your money.

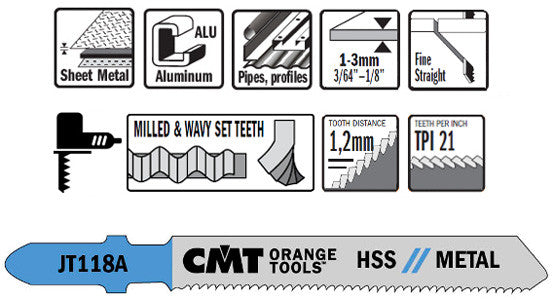

HSS (high speed steel). For use when cutting harder materials, such as metals, aluminium and non-ferrous metals.

Geometry is important.

Milled and side set teeth. Jig saw blades featuring this kind of geometry feature a quick rough cut into soft/hardwood, aluminium, plastic and non-ferrous metals.

Milled and wavy set teeth. Suitable for fine straight cuts into plywood, soft steel, aluminium, non-ferrous metals and plastic.

Ground and side set teeth. To be used for quick cuts in wood.

Ground and taper ground teeth. This geometry delivers fine and clear cuts in wood and plastic.

Click here to download the guide to choose the most suitable jig saw blade to fit your woodworking needs.

HSS JIGSAW BLADES

QUESTIONS & ANSWERS

Have a Question?

Be the first to ask a question about this.