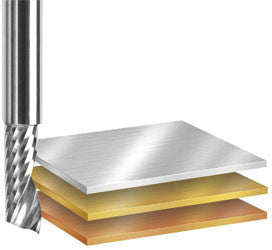

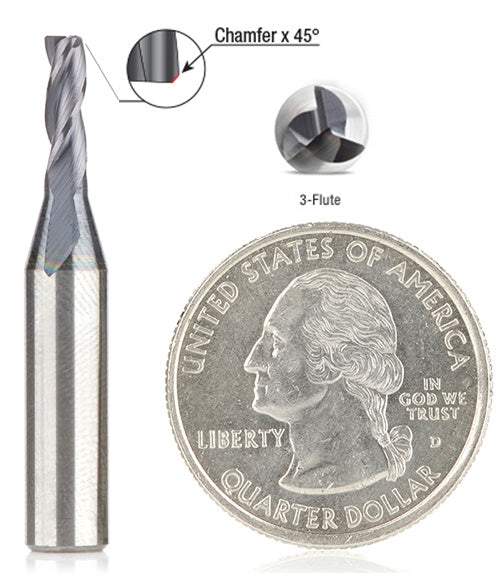

These router bits are manufactured from ultra-fine micrograin carbide and feature a 30° Center Cutting Mill End with a 45° corner chamfer (for extra strength) up-cut design and very importantly Aluminum Titanium Nitride (AlTiN) coating for superior cut quality.

Increase the ruggedness of your solid carbide end mill's number one major wear point by the addition of corner chamfers that enhance the edge strength.

Excellent for cutting:

- Stainless Steel

- Steel

- Cast Iron

- Composites

- Low Carbon Steel

- Magnesium

- Metal Composite Material (MCM)

- Plastics

- Super Alloys

- Titanium (up to 40HRc Hardness)

These bits are perfect for the signmaking industry. The special carbide grade combined with the AlTiN coating gives an amazing performance. The unique corner chamfer gives the bits great strength.

AlTiN coating has many benefits:

- Extra wear resistance

- Allows for faster feed and speed rates

- Cutting edge protected from wear

- Better chip evacuation

- Less heat build-up

- Superior cutting quality and extended tool life

WARNING: Inspect cut quality and adjust feed and speed accordingly. Care should be taken to observe proper feeds and speeds according to the workpiece material to avoid damage.

Note: For optimal results and extended tool life, use mist lubricant system or air cooling.

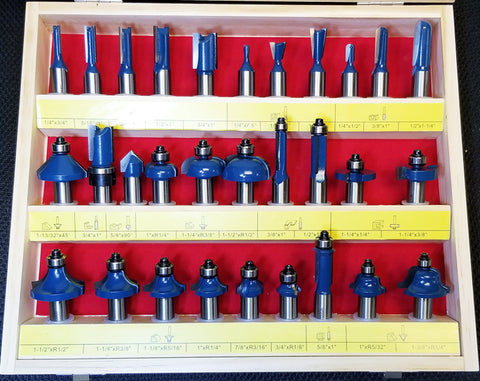

CNC STEEL, STAINLESS STEEL, & COMPOSITE UPCUT SPIRAL ROUTER BITS

QUESTIONS & ANSWERS

Have a Question?

Be the first to ask a question about this.