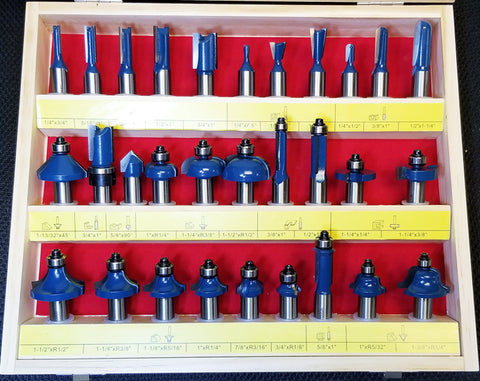

With the spiral cutting angle, the solid carbide spiral flush trim bits with double bearing allow for razor-sharp trimming, providing more efficient chip ejection than standard flush trim bits. In production settings, these bits will run cooler and the edges will stay sharper, last longer and increase shop productivity.

SPIRAL FLUSH TRIM ROUTER BITS

QUESTIONS & ANSWERS

Ask a Question-

upcut vs downcut? what the difference? edge trimming 1 3/4 walnut for cutting board. 2 in shank preferred

Upcuts are the preferred method in a router table and down cut is preferred in the handheld applications. It's all about the direction on the chip and pressure created by the spiral motion in order to help steady and secure the workpiece. Also, down cuts are hardly ever used in router tables.