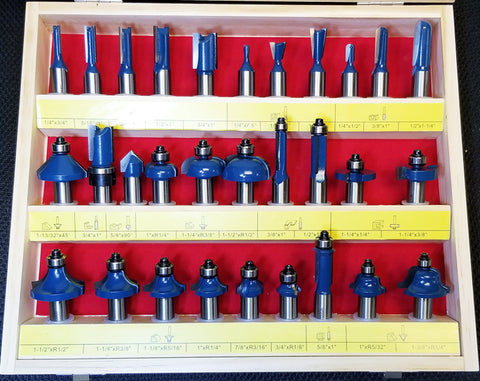

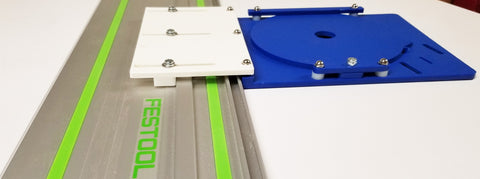

The template must be securely fastened to the work piece. When choosing a bit, carefully consider the thickness of the template and all the implications of the cut. Opt for the shortest bit possible for the project you are working on. When selecting a pattern bit, be sure to keep in mind the complexities of the pattern and the tightest radius in the pattern. Always use the largest diameter bit that is compatible with the pattern for the best finish quality and the greatest ease of use. Larger diameter bits also allow for larger bearings which last longer in heavy use applications. Always remember to check the bit clearance below your work so that you don’t accidentally cut into your workbench or other support structure. Be sure to maintain bearing for longer life and smoother cuts.

PATTERN ROUTER BITS 1/2" SHANK

QUESTIONS & ANSWERS

Ask a Question-

Do you sell replacement parts if needed for these cutters?

We do! For pattern bits, the shank size would be the ID (inside diameter) of the bearing. The OD (outside diameter) would equal the diameter of the bit. Stop collars and bearings can be found here:

https://www.woodline.com/collections/bearings-spare-parts